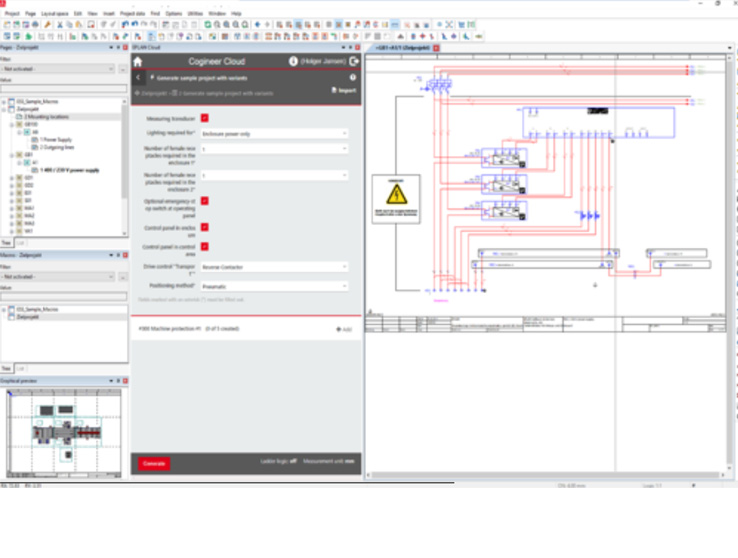

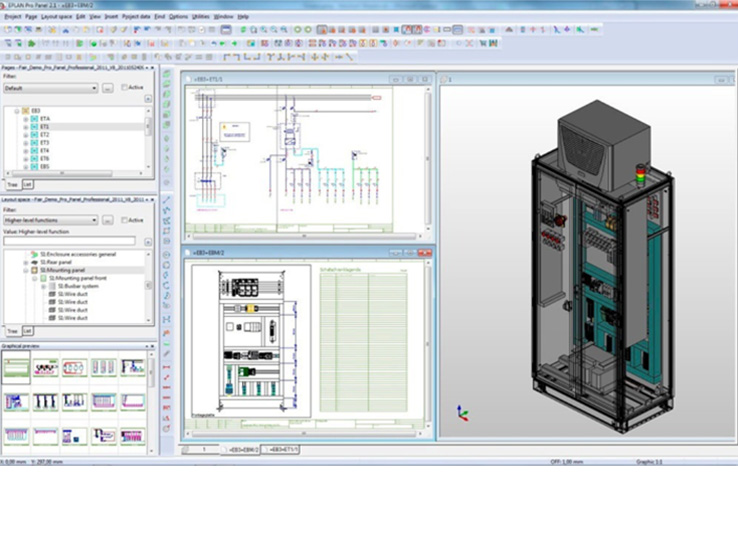

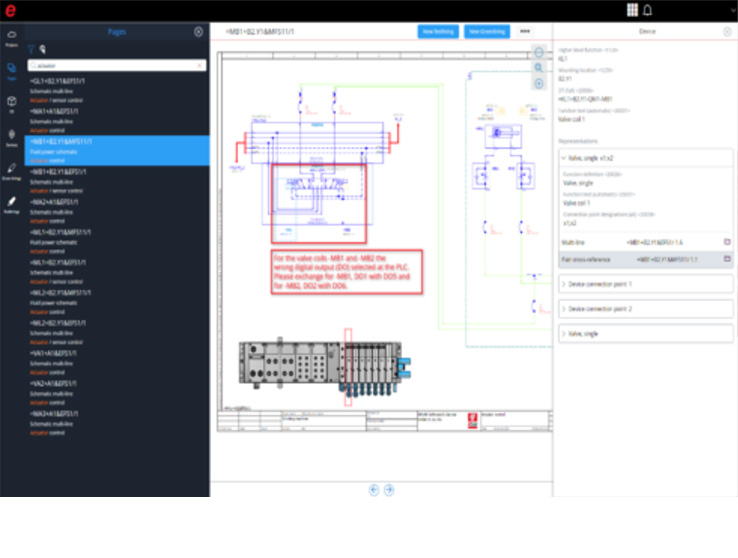

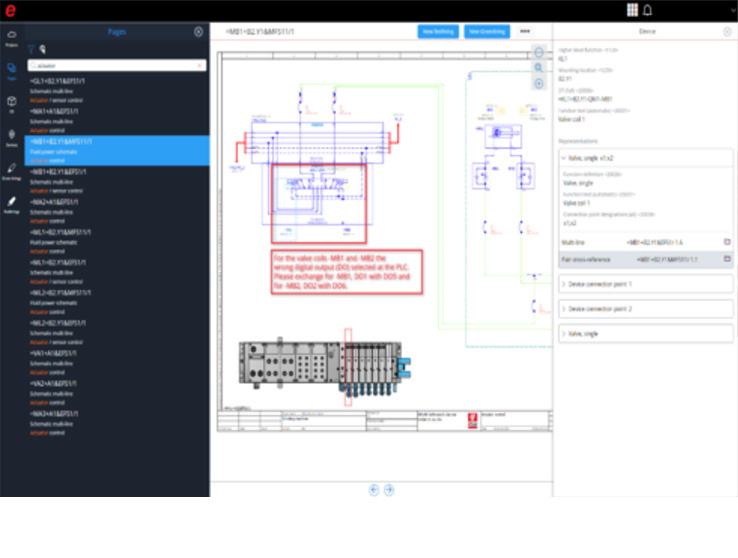

Engineering

Your Benefit

- Database-supported creation of function-oriented schematics

- High potential for standardisation and automation in project creation by using macro technology

- Direct access to a variety of manufacturer data in the EPLAN Data Portal

- Graphic and object-oriented work methods possible for engineering design

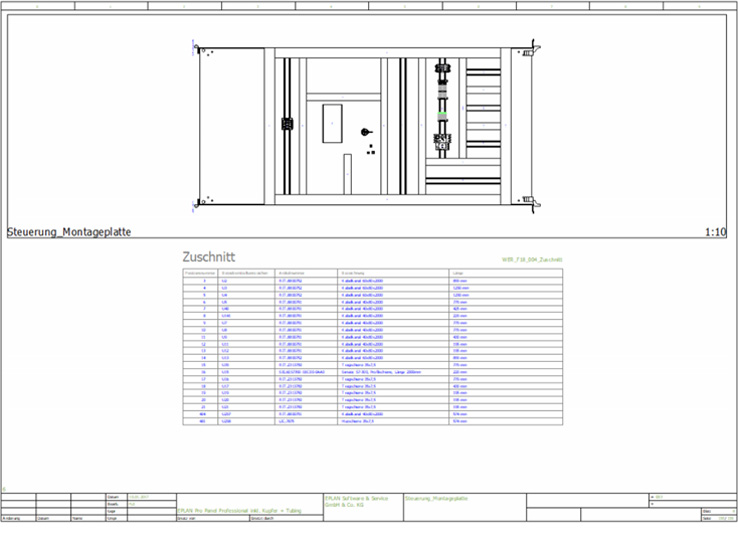

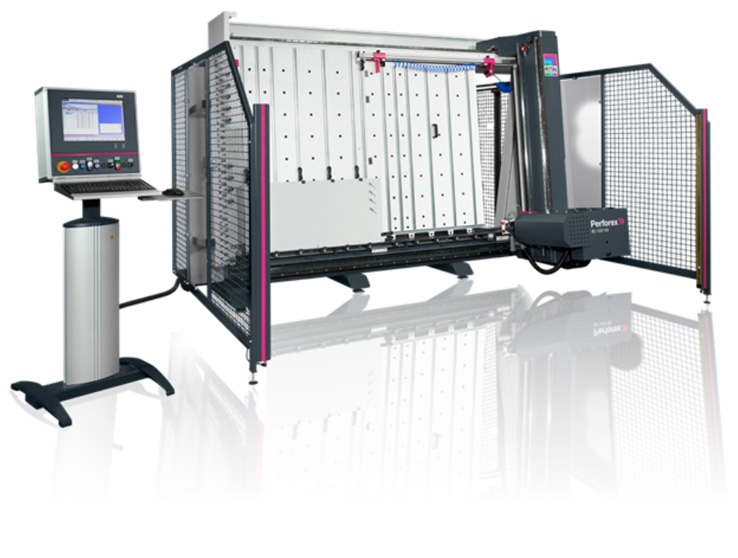

Cutting

Your Benefit

- Easy and intuitive placement of mounting rails and wire ducts

- Providing data from the digital twin for cutting DIN rails and wire ducts to length

- Providing data sets in XML format

- Time savings of up to 51% thanks to fully automatic terminal strip production

Panel Modification

Your Benefit

- Drilling information is transferred to the workpiece by way of components from the database

- Simplified data management via standardised drilling patterns

- Automatically create drilling and milling data using the digital twin

- Time savings of up to 89% thanks to fully automated preparation of the order at the machining centre

- Making changes is easy and there’s an overview of consistent data

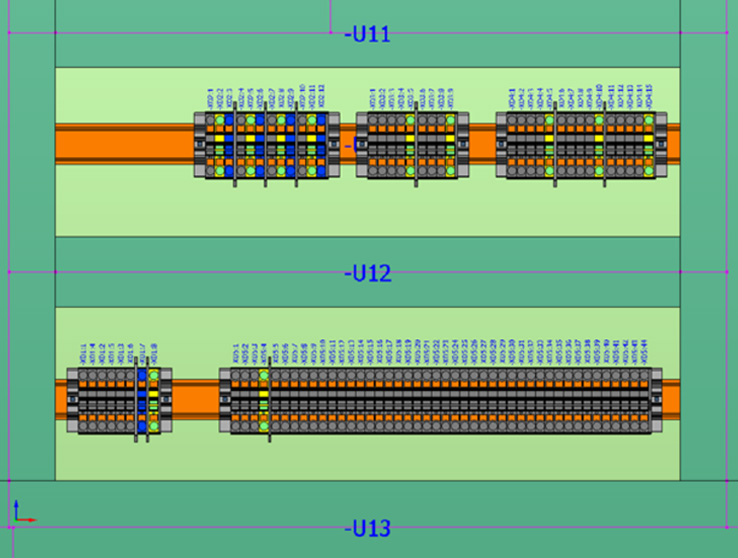

Terminal Strip Assembly

Your Benefit

- Easy creation of the digital twin for panbel building

- Assemble and assign terminal strips in engineering

- Complete work steps in parallel by pre-assembling terminal strips

- Test and complete terminal strips using the manufacturer’s software

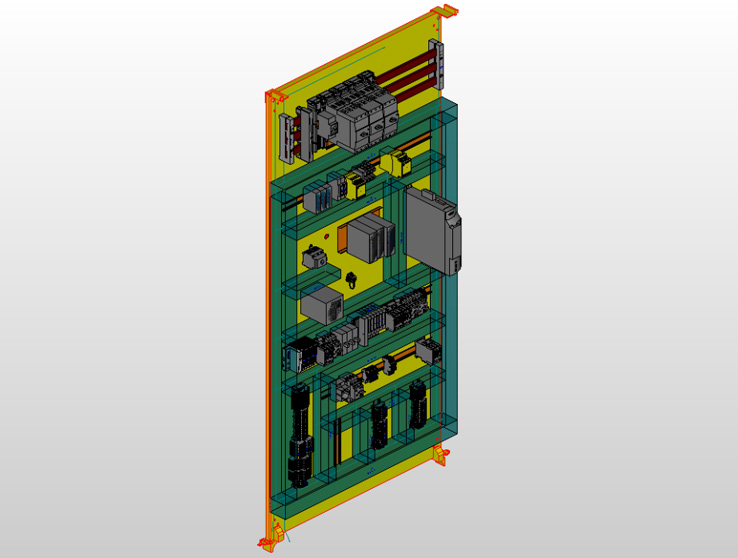

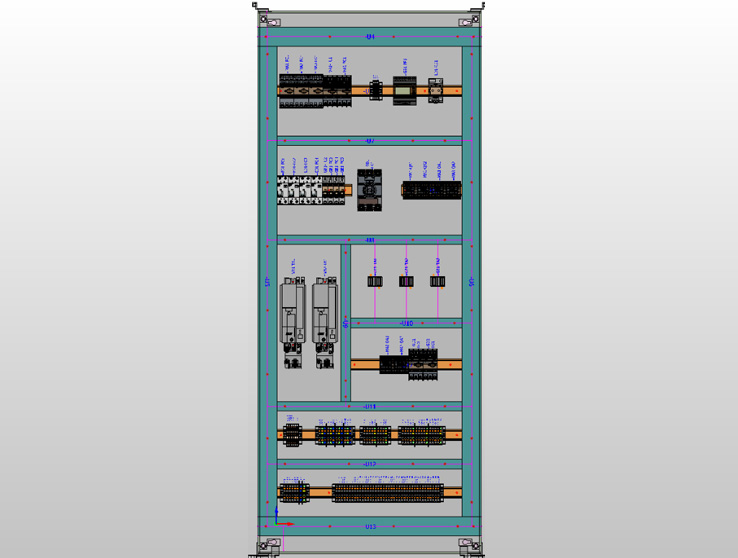

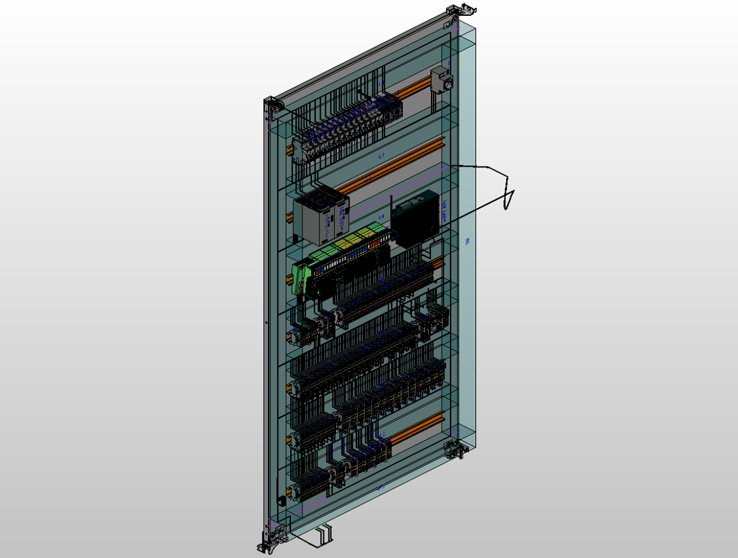

Mechanical Installation

Your Benefit

- Easy creation of the digital twin as the foundation for enclosure production

- Collision checks in the model reduce the need for corrections later, saving time and money

- Heat sources are made apparent early in the planning phase

- Visual guidance for assembly via 2D and 3D manufacturing documentation

- Providing digital manufacturing documentation for paperless production

- Parallel processing steps by outputting cutting lists

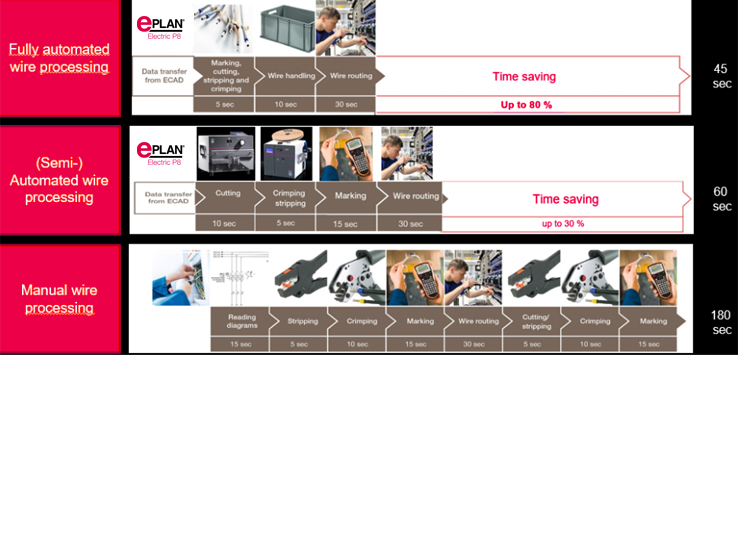

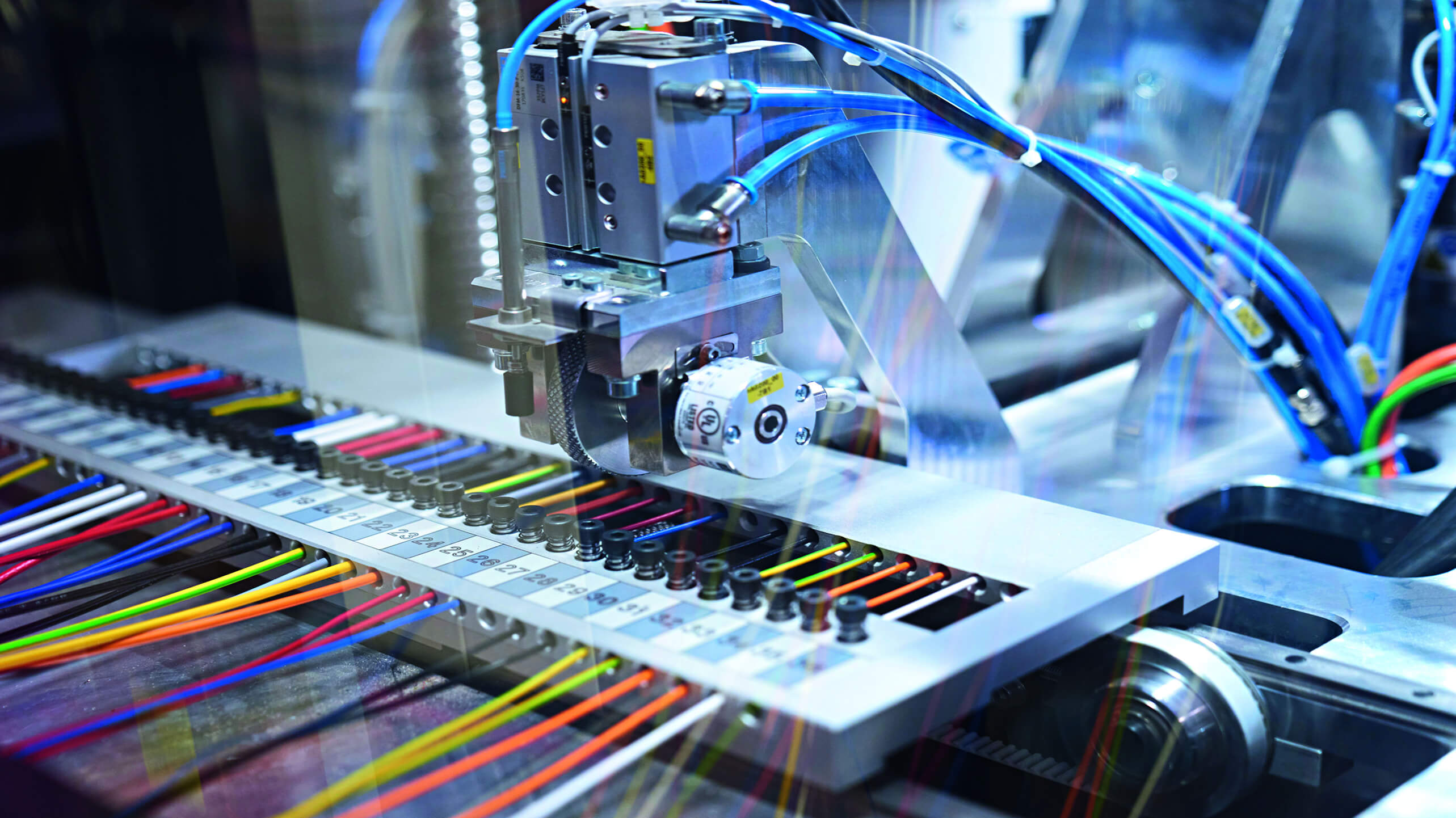

Wire Fabrication

Your Benefit

- Pre-assembly offers the highest potential for savings for the entire control cabinet production

- Length, colour, cross-section and target wiring are all automatically determined

- Exporting of data sets to wiring processing machines or service providers

- Transparent change process using change lists

Wiring

Your Benefit

- Rule-based routing for wiring from the 3D model of the schematics

- Derive information from the digital twin, for instance about the length, colour and cross-section of wires and termination, source and destination

- Optimising wiring through the use of visualisations and by providing all data in digital form

- Time savings of 20% thanks to visual source/destination representation in EPLAN Smart Wiring

- Information about routing paths are also provided in 3D

- Simplified representation enables wiring to be completed without wiring expertise

- Status overview simplifies project handover

Testing

Your Benefit

- Preventing potential mistakes during commissioning

- Providing digital project data

- Easy testing without schematics via step-by-step instructions

- All necessary information is available in digital form, from the connection point to the exact routing path – in 3D as needed

- Status information makes transferring projects between various employees easier and enables project monitoring

- Potential savings of up to 20% via the digital testing process in EPLAN Smart Wiring